Mastering Metal Laser Engraving: A Comprehensive Guide for Beginners

Introduction

Metal laser engraving is a versatile and precise method for creating detailed designs on various metal surfaces. For beginners, understanding the basics is crucial to mastering this craft. This guide will provide an overview of the process, essential tools, and practical tips to help you start your engraving journey with confidence.

Understanding Metal Laser Engraving

What is Metal Laser Engraving?

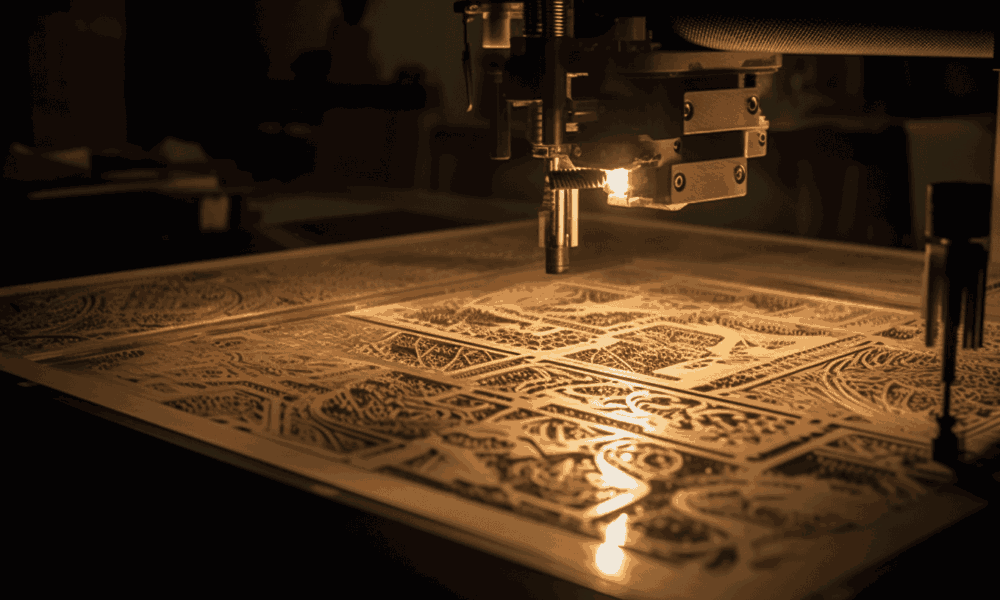

Metal laser engraving is a process that uses a focused laser beam to etch designs, patterns, or text onto metal surfaces. The laser’s intense heat removes material or alters the surface, creating a permanent mark. This method is popular for its precision and ability to produce intricate details.

How Does It Work?

The laser beam is controlled by a computer, following a design created in specialized software. The laser interacts with the metal’s surface, either vaporizing a thin layer or causing a chemical reaction that changes the metal’s appearance. The result is a precise, durable engraving.

Types of Lasers Used for Metal Engraving

- Fiber Lasers: Ideal for metals, offering high precision and speed.

- CO2 Lasers: Less common for metal but effective for certain applications.

- Nd

Lasers: Used for deep engraving and cutting.

Common Materials Used in Metal Engraving

- Stainless Steel

- Aluminum

- Brass

- Titanium

Each metal has unique properties that affect how it responds to laser engraving, making material selection important.

Essential Tools and Equipment

Laser Engraving Machines

Selecting the right laser engraving machine is critical. Fiber lasers are the most common choice for metal engraving due to their efficiency and precision. These machines come in various power levels, suited for different types of projects.

Design Software

Software like Adobe Illustrator, CorelDRAW, and AutoCAD are commonly used to create designs for engraving. The software translates the design into instructions for the laser.

Safety Equipment

Laser engraving involves intense light and potential fumes, making safety gear essential. Protective eyewear, proper ventilation, and gloves are recommended.

Step-by-Step Guide to Metal Laser Engraving

- Preparing Your Design

- Create or import your design using design software.

- Convert the design into a compatible file format (e.g., .svg, .dxf).

- Choosing the Right Metal

- Select a metal suited to your project and laser type.

- Clean the metal surface to ensure proper engraving.

- Setting Up the Laser Machine

- Calibrate the laser, adjusting power, speed, and focus based on the metal.

- Secure the metal on the engraving bed.

- The Engraving Process

- Run a test engraving on a sample piece.

- Start the engraving, monitoring the machine to ensure accuracy.

- Finishing Touches

- Clean the engraved piece to remove debris.

- Inspect for quality and make any necessary adjustments.

Tips for Achieving High-Quality Results

- Adjust Laser Settings: Tailor power and speed settings based on the metal and design complexity.

- Precision and Detail: Use high-resolution designs and slow engraving speeds for intricate details.

- Avoid Common Mistakes: Ensure proper focus and avoid over-engraving.

- Troubleshooting: Address issues like uneven engraving or material burning by adjusting settings.

Applications of Metal Laser Engraving

Metal laser engraving has diverse applications across various industries:

- Jewelry: Personalized engravings on rings, bracelets, and necklaces.

- Industrial Parts: Marking serial numbers, barcodes, and logos on tools and machinery.

- Personalized Gifts: Custom designs on items like pens, flasks, and watches.

- Art: Creating intricate designs on metal sculptures or decorative pieces.

Emerging Trends

Advancements in laser technology are expanding the possibilities of metal engraving, allowing for more detailed and complex designs in shorter timeframes.

Conclusion

Metal laser engraving offers endless possibilities for creativity and precision. By understanding the basics and following best practices, beginners can quickly master this art. Experimentation and practice are key to refining your skills and producing high-quality engravings. Tools like those offered by OMTech can be particularly useful, as they provide reliable and accessible laser engraving machines for various needs. For those eager to dive deeper, numerous resources are available to continue learning and exploring this fascinating craft.